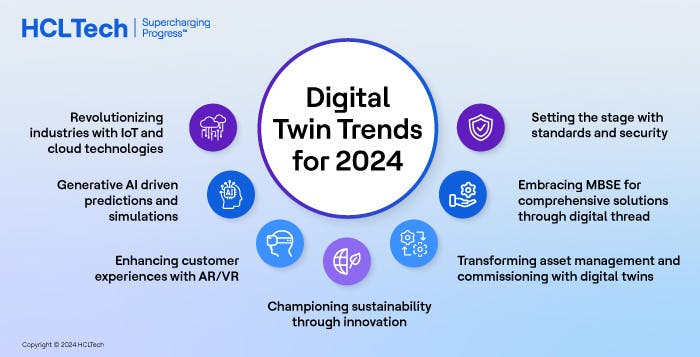

As we navigate through 2024, the digital twin technology landscape is experiencing a remarkable transformation, driving innovation and operational excellence across various industries. IDC projects the digital twins' market to grow at a five-year CAGR of 28.5%. According to a McKinsey survey, 86% of respondents across industries said digital twins applied to their organization, especially in production operations.

From enhancing IoT and cloud-based integrations to spotlighting sustainability and redefining asset management, digital twins are becoming an integral component of business strategy and the digital transformation vision. Let's explore how these trends practically influence industries and what they signify for businesses looking to stay ahead.

Revolutionizing industries with IoT and cloud technologies

The fusion of IoT with digital twin technology is revolutionizing industry standards by enabling unprecedented connectivity and data analytics. This is not just about technology talking to technology; it's about replicating real-world behavior in the digital world and using these technology conversations to improve real-world processes/assets, making them more efficient and reliable. For instance, in manufacturing, digital twins allow for the real-time monitoring and adjustment of production lines, leading to significant reductions in downtime and wastage.

Generative AI-driven predictions and simulations

The application of generative AI (GenAI) within digital twins represents a major leap in predictive analytics and simulation. Businesses can now create highly accurate models of their operations, products, assets or services, enabling them to anticipate outcomes and refine strategies with a much higher degree of precision. In the automotive sector, for example, companies use digital twins in Software-Defined Vehicles (SDV) to simulate vehicle performance under various conditions, substantially accelerating the development cycle and enhancing product safety and reliability.

GenAI-based digital twins act as active advisors, augmenting humans in effective decision-making. For instance, digital twins in the supply chain can improve resilience and detect slippages and failures in the partner ecosystem with self-healing and auto-correction recommendations through predictive analytics with better forecasting techniques.

Enhancing customer experiences with AR/VR

AR and VR technologies are redefining customer engagement by providing immersive experiences that were previously unimaginable. AR/VR acts as a lens to view and interact with 3D content from the digital twin. For instance, in the manufacturing industry, digital twins enhanced with AR/VR allow OEMs to explore and customize their future products, processes and plant layouts in a virtual environment. This improves customer satisfaction and significantly streamlines the design and decision-making process. Another example is from the healthcare industry, where digital twins, along with AR/VR, optimize the flow of patients and test how customers experience a physical facility.

Championing sustainability through innovation

Digital twins are at the forefront of promoting sustainability within businesses. By accurately modeling energy consumption and the environmental impact of materials and processes, companies can make more informed decisions that align with sustainability goals. One of the key usages of digital twins are in developing and managing sustainable smart infrastructure and distributed resources. This covers the wide spectrum like transportation (roads, rail, aero, shipping network), water infrastructure, smart cities, traffic systems and social infrastructure like health and education.

Infrastructure companies are using digital twins in a two-step process: first, building infrastructure in digital form to run simulations and optimizations, and then building it physically. This helps visualize and track the construction progress of existing infrastructure and services along with the planned one, including providing feedback.

In the utility sector, digital twins are being used to optimize energy distribution networks, offering smart charging infrastructure for EV users, reducing waste and lowering carbon emissions, also to take decisions on sustainable reuse and recycling of EV batteries.

Transforming asset management and commissioning with digital twins

A key component of any industry includes its assets, which can be legacy or smart and connected assets. The assets can be wind turbines, solar panels, smart charging stations, EV Batteries, welding robots, HVAC systems, telecom towers, medical and hi-tech equipment, oil and gas assets, power grid assets and much more. The major portion of the CAPEX and OPEX is spent on managing and maintaining these assets with different configurations. Digital twins are redefining how companies track, maintain and optimize their physical assets.

This approach offers a unified view of asset performance and health, facilitating predictive maintenance and operational adjustments. For example, industries with extensive infrastructure, such as telecommunications or transportation, predict and prevent failures before they occur, ensuring uninterrupted service and enhanced customer satisfaction.

A growing trend is using digital twins while commissioning new assets. We can test various scenarios on the digital twin first before taking the assets to the physical world, reducing the time and cost of operationalizing new asset commissioning.

Embracing MBSE for comprehensive solutions through digital thread

The shift from model-based design to Model-Based Systems Engineering (MBSE) marks a significant evolution in how businesses approach system development. MBSE helps the manage the production and process of digital twins, where data continuity is achieved through the digital thread. Digital thread ties the MBSE process together by embodying all data related to digital twins.

By adopting a holistic system engineering approach, industries, especially Aerospace and Defense (A&D), achieve unparalleled efficiency and coherence in complex projects. Many companies are leveraging the power of digital twins in MBSE as a critical step toward integrating and optimizing all facets of system design and lifecycle management, ensuring success in increasingly competitive markets.

Setting the stage with standards and security

Establishing common frameworks and standards for digital twins is critical for fostering innovation and ensuring compatibility across different systems and industries. Organizations such as the Digital Twin Consortium, Industrial Digital Twin Association and OPC Foundation, along with industry, academia and government experts, are working in this area, providing a foundation for businesses to build upon.

Moreover, as digital twins become more prevalent, the importance of securing these systems against unauthorized access and cyber threats has come to the forefront. Companies are increasingly focusing on incorporating robust security measures into their digital twin strategies, ensuring the integrity and confidentiality of their data.

As we look toward the rest of 2024 and beyond, the practical applications and business use cases for digital twin technology continue to expand. From optimizing operations and enhancing customer experiences to driving sustainability and ensuring asset longevity, digital twins are proving to be an indispensable tool in the modern business landscape.

With contributions from – Girish Sohoni, Practice Manager, Engineering and R&D Services, HCLTech.